#L Foundation Anchor Bolt

Explore tagged Tumblr posts

Text

Foundation Bolt Manufacturer

Foundation bolts are essential components used in the construction and installation of heavy machinery, structural frameworks, and large equipment. These bolts anchor various structures to the foundation, ensuring stability and safety. Typically made from high-strength steel or other durable materials, foundation bolts are designed to withstand substantial stress and load-bearing forces. They come in various sizes and shapes, including L-shaped, J-shaped, and straight bolts, depending on the specific needs of the project. The bolts are often embedded in concrete or anchored to the base of a structure, offering a secure fastening solution. The precise design and quality of foundation bolts are critical for ensuring the integrity and longevity of buildings, bridges, and industrial equipment.

0 notes

Text

Why Foundation Bolts Are Critical for Structural Integrity | Essential Insights

This article helps in undertsanding Foundation bolts as, they are fasteners designed to anchor structural elements or machinery to a concrete foundation. They work hand in hand with shim sheet metal and stainless steel shims for alignment and stability.

Key Features of Foundation Bolts:

Components: Bolts, industrial washers, and nuts.

Design Options: Straight, L-shaped, or J-type foundation bolts.

Applications: Securing steel columns, heavy machinery bases, and structural beams.

This article also helps in understanding the types of foundation bolts is crucial for choosing the right one for your project:

Straight Bolts: Used for light to moderate loads, often with tab washers.

L-Shaped Bolts: Ideal for medium loads and extra grip, often secured with hex washers.

Foundation J Bolts: Designed for high-stress situations and work effectively with conical washers.

Expandable Bolts: Perfect for retrofitting and post-installation into concrete.

The material of foundation bolts determines their performance and compatibility with accessories like ss shim plates and shim sheet metal.

Carbon Steel: Cost-effective and robust but less resistant to corrosion.

Stainless Steel: Highly durable, corrosion-resistant, and ideal for use with self-locking washers.

Galvanized Steel: Coated with zinc for added corrosion resistance, often used with countersunk washers.

Foundation bolts are indispensable in construction, ensuring stability, safety, and durability. By pairing them with components like shim washers, conical washers, and wedge lock washers, you can enhance their effectiveness and longevity.

Whether it’s skyscrapers, machinery, or bridges, the integrity of a structure begins with the right foundation—and the right bolts. Ensure your next project stands the test of time by choosing high-quality foundation bolts, precision-aligned with shim sheet metal, and secured with industrial washers.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

Link

Why Foundation Bolts Are Critical for Structural Integrity | Essential Insights

#FoundationBolts#StructuralIntegrity#ConstructionInsights#EngineeringBasics#BuildingSafety#StructuralEngineering#FoundationMatters#CriticalComponents#EngineeringTips#StructuralStability

0 notes

Text

Shakti Industries provide high quality and durable bolts that can be used in many different types of construction work and industrial applications. An L-shape foundation bolt is designed and manufactured accurately and made from strong raw materials utilizing advanced technology for excellent performances to meet high-grade requirements for strength and robustness in the industry. Shakti Industries Udaipur is trusted L-Shaped Foundation Bolts supplier in India, can offer different sizes and options according to the requirements of projects. We are guaranteed that the L-type foundation bolts will minimize risks on structure and maximize stability through anchoring solutions used for heavy machinery installation, structural foundation, and civil engineering projects. Shakti Industries Udaipur continues to be the most preferred L-Type Foundation Bolt Manufacturer in India by holding quality and customer satisfaction while delivering to clients throughout the country. We have the most experienced engineers and technicians in our team, which check every bolt on grounds of performance and durability; hence, we are considered as a prominent L-Shaped Foundation Bolts Supplier in India for the business.

0 notes

Text

Types of Bolts: A Comprehensive Guide

Ananka Group is the Best Bolt Manufacturer in India. In many different industries, bolt is an essential component of the supply and transportation networks. It is used to link or connect objects together and is simple to assemble and disassemble. High-tensile bolts are important because of their high tensile strength and resistance to compression fitting in the building of steel structures.

1. Hex Bolts

Hex bolts are named for their hexagonal heads and are one of the most commonly used types of bolts. They come in various grades and materials, making them versatile for different applications.

Uses: Hex bolts are widely used in construction, machinery, and automotive industries. They are ideal for joining wood, metal, and other materials.

Characteristics: They are available in both coarse and fine thread varieties and can be used with a corresponding hex nut or tapped hole.

2. Carriage Bolts

Carriage bolts feature a round, domed head and a square neck that prevents the bolt from turning when the nut is tightened.

Uses: Commonly used in wood-to-wood or wood-to-metal applications such as furniture assembly, fencing, and deck building.

Characteristics: The square neck grips into the material to prevent the bolt from spinning during installation.

3. Lag Bolts

Lag bolts, also known as lag screws, are large, heavy-duty bolts with a hex head.

Uses: Ideal for heavy-duty applications such as securing large timbers, wood construction, and outdoor projects like decking.

Characteristics: They have sharp, coarse threads that provide a strong grip in wood.

4. Eye Bolts

Eye bolts have a looped head that can accommodate ropes, cables, or chains.

Uses: Often used for lifting, rigging, and anchoring applications. They are also used in light fixtures, electrical wiring, and marine hardware.

Characteristics: Available in various materials, including stainless steel for corrosion resistance in marine environments.

5. Anchor Bolts

Anchor bolts are designed to attach structures or machinery to concrete.

Uses: Widely used in construction for securing buildings, bridges, and heavy machinery to concrete foundations.

Characteristics: They come in different types, such as L-shaped, J-shaped, and wedge anchors, each suited for specific applications.

6. U-Bolts

U-bolts are shaped like the letter "U" with threads on both ends.

Uses: Commonly used to secure pipes, conduit, or other round objects to a surface. They are also used in automotive applications to attach exhaust systems.

Characteristics: They provide a strong and stable attachment for cylindrical objects.

7. Flange Bolts

Flange bolts have a built-in washer (flange) under the head that distributes the load and provides a larger bearing surface.

Uses: Frequently used in the automotive industry for securing frames, engines, and transmission systems. They are also used in plumbing and construction.

Characteristics: The flange reduces the need for a separate washer, simplifying installation.

As India's largest Bolt Manufacturer, Our specialty is larger diameter bolts and nuts made of stainless steel with higher tensile strength. They are essential components of many industries, including home goods, construction, manufacturing, and transportation. Also we are India's largest Fasteners Suppliers. We provide fastener grades that satisfy all international and national specifications. We also specialise in stainless steel Hex bolts, nuts, Stud bolts, and other fasteners.

0 notes

Text

Fondation Bolts

Foundation Bolts: Anchors of Stability

Foundation bolts are unsung heroes in the world of construction, silently playing a pivotal role in ensuring the stability and resilience of structures. These bolts serve as the crucial link between a building and its foundation, anchoring the two together to withstand the test of time and external forces.

Types: Foundation bolts manufacturers come in various types, each designed to meet specific structural requirements. J-type bolts, resembling the letter 'J,' provide a strong hold, while L-type bolts, shaped like an 'L,' offer stability at a specific depth. T-type bolts feature a flat, horizontal base for robust anchoring, and U-type bolts provide flexibility for adjustments during construction.

Materials: Crafted from high-strength materials such as carbon steel or alloy steel, foundation bolts are engineered to endure substantial loads while resisting corrosion. In corrosive environments, stainless steel bolts become the material of choice, ensuring longevity in challenging conditions.

Installation: The installation process of foundation bolts is a critical phase in construction. Positioned strategically during the initial stages, these bolts are embedded into the concrete foundation. Precision in alignment is crucial to ensure the subsequent attachment of structural elements. Once the foundation sets, nuts and washers are fastened onto the exposed ends, locking the bolts securely in place.

Importance: The significance of foundation bolts lies in their ability to provide structural stability, distribute loads evenly, and enhance the overall safety of a building. In seismic-prone regions, these bolts act as essential safeguards, preventing excessive movement and potential structural failure.

In essence, foundation bolts are the anchors that silently contribute to the resilience and longevity of structures. Their installation, often overlooked by many, is a meticulous process that ensures the very foundation of a building is firmly anchored, standing as a testament to their importance in the realm of construction.

1 note

·

View note

Text

The Hidden Power of Foundation Bolts: Discover the Key to a Rock-Solid Foundation

Introduction: Beneath the surface of every solid structure lies a hidden power, a key element that ensures its unwavering strength and stability: foundation bolts. Often overlooked, these unassuming fasteners play a vital role in creating a rock-solid foundation. From towering skyscrapers to humble homes, understanding the hidden power of foundation bolts unveils their crucial role in constructing structures that stand the test of time.

The Foundation's Backbone: Foundation bolts act as the backbone of any construction project, providing the essential link between the foundation and the superstructure. These robust metal bolts are strategically embedded in concrete or masonry, securing the structure firmly to the ground. By creating a strong connection, foundation bolts counteract the forces of gravity, external loads, and environmental factors that can jeopardize the stability of the building.

Anchoring for Stability: The primary function of foundation bolts is to anchor the structure to the foundation. This anchoring process prevents excessive movement, ensuring that the building remains stable and resistant to forces such as wind, earthquakes, and vibrations. Foundation bolts work in conjunction with the foundation to distribute the loads evenly, minimizing the risk of structural failure and guaranteeing long-term stability.

Types and Configurations: Foundation bolts come in various types and configurations, each designed to suit specific construction requirements. J-bolts, L-bolts, and U-bolts are commonly used, with each type offering distinct advantages in different scenarios. These bolts can be customized in terms of size, shape, and threading, allowing them to accommodate specific load demands and structural designs.

Precision Installation: The installation of foundation bolts demands precision and expertise. During the construction phase, anchor bolt locations are meticulously planned based on architectural and engineering specifications. Once the foundation is ready, the bolts are embedded and aligned precisely. Proper alignment ensures that the superstructure can be securely attached, minimizing any potential structural weaknesses. The bolts are then tightened to the specified torque, guaranteeing a strong and secure connection.

Enhancing Durability: Foundation bolts play a crucial role in enhancing the durability of the structure. Galvanized or stainless steel bolts are often used to provide resistance against corrosion, which can weaken the bolts over time. The selection of appropriate materials and coatings ensures that the foundation bolts remain robust, contributing to the overall longevity and integrity of the structure.

Beyond Buildings: Industrial Applications: The hidden power of foundation bolts extends beyond traditional building construction. In industrial settings, such as manufacturing plants and infrastructure projects, foundation bolts are instrumental in securing heavy machinery, equipment, and structural components. These bolts provide the necessary stability and rigidity to support the operational needs of various industries, ensuring safety and efficiency.

Conclusion: As we admire magnificent structures, it is essential to recognize the hidden power of foundation bolts—the silent heroes that establish a rock-solid foundation. From providing stability and load distribution to enhancing durability, these unassuming fasteners play a vital role in constructing structures that withstand the test of time. Understanding the hidden power of foundation bolts sheds light on the critical elements that contribute to the strength and longevity of our built environment

0 notes

Photo

M10 M12 M16 M20 M24 J / L Foundation Anchor Bolt

click here to see more of this product

#L Foundation Anchor Bolt#M10 L Foundation Anchor Bolt#M12 L Foundation Anchor Bolt#l anchor bolt#l type anchor bolt#foundation bolt (anchor)#l type anchor bolt dimensions#l type anchor bolt price philippines#l-bolt#l bolt price#foundation bolt for cot bed

0 notes

Photo

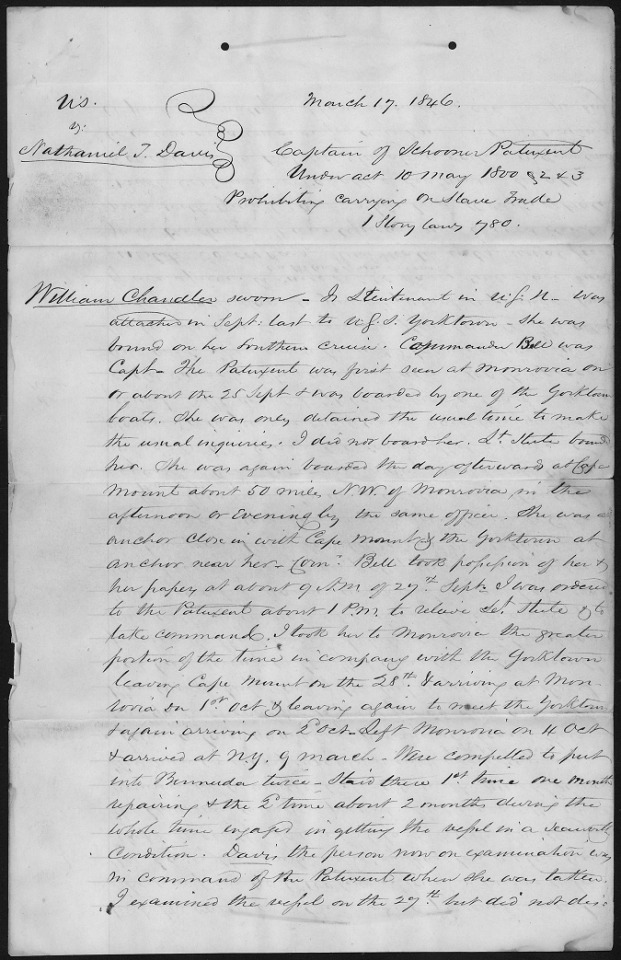

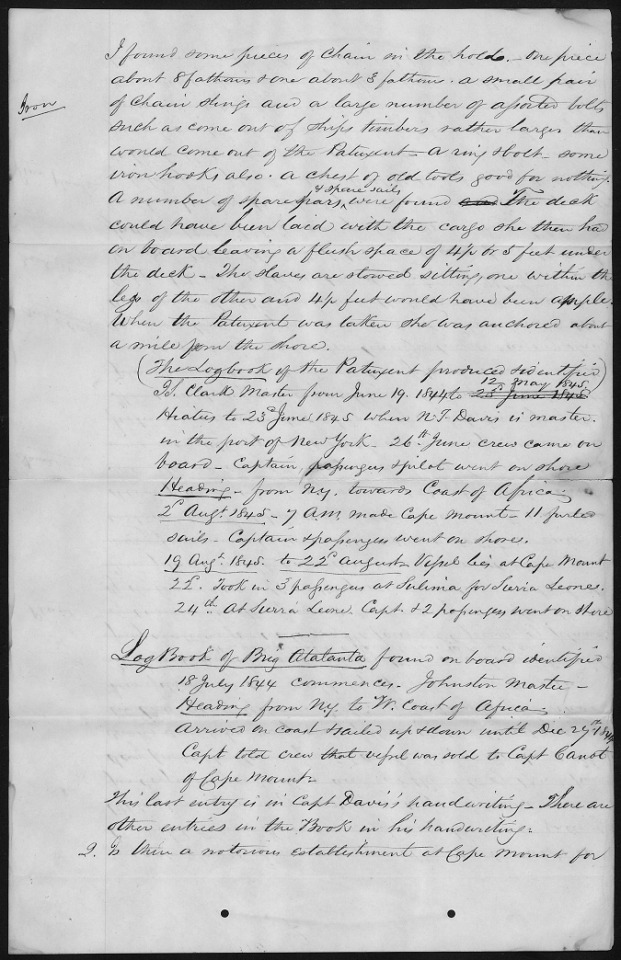

Deposition of William Chandler regarding an alleged slave ship, 3/17/1846

He testifies that the ship carried rations for enslaved people--a pound of rice and a pint of water per person per day--as well as a 4 ½’ high space for them to be transported, each sitting between the legs of the next person.

File Unit: United States v. Nathaniel T. Davis, 3/17/1846 - 5/4/1846

Series: Criminal Case Files, 1790 - 1912

Record Group 21: Records of District Courts of the United States, 1685 - 2009

Transcription:

US MARCH 17. 1846

vs

Nathaniel J. Davis Captain of Schooner Patuxent

Under act 10 May 1800 2 & 3

Prohibiting carrying on slave trade

1 Story laws 780

William Chandler sworn- Is Lieutenant in U.S.N. - was attached in Sept. last to U.S.S. Yorktown - she was bound on her Southern cruise. Commander Bell was

Capt the Patuxent was first seen at Monrovia on or about the 25 Sept and was boarded by one of the Yorktown boats. She was only detained the usual time to make

the usual inquiries. I did not board her. Lt. [illegible] boarded her. She was again boarded the day afterwards at Cape Mount about 50 miles N.W. of Monrovia in the

afternoon or evening by the same officer. She was anchor close in with Cape Mount & the Yorktown at anchor near her - Comr Bell took possession of her & her paper, at about 9 A.M. of 27th Sept. I was ordered to the Patuxent about 1 P.M. to relieve Lt [illegible] & to take command. I took her to Monrovia the greater portion of the time in company with the Yorktown leaving Cape Mount on the 28th. I arriving at Monrovia on 1st Oct & leaving again to meet the Yorktown & again arriving on 2 Oct. Left Monrovia on 4 Oct & arrived at N.Y. 9 March. Were compelled to pull into Bermuda twice - Staid there 1st time one month repairing & the 2ᵈ time about 2 months during the whole time engaged in getting the vessel in a seaworthy condition. Davis the person now on examination was in command of the Patuxent when she was taken. I examined the vessel on the 29th but did not dis

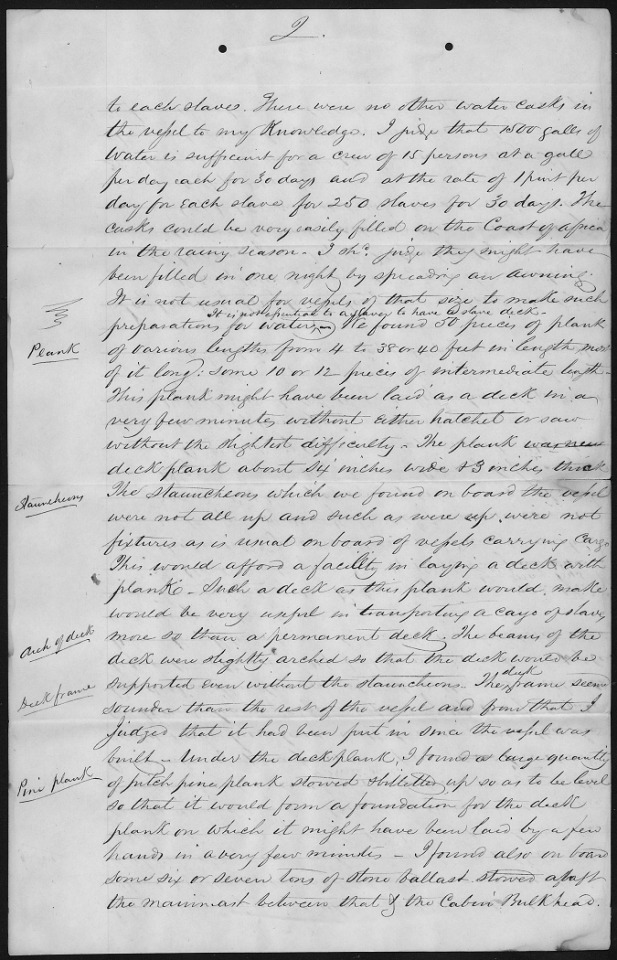

[page 2]

turb the cargo or rather made a personal inspection. She was from 90 to 100 tons. I found 5 persons on board W. T. Davis the Master -- Thos l. Shaw the mate -- and Joseph Morrell, James C. .Clark & John Smith. -- The three men are now present. That is about the usual number for a vessel of that size in the mercht service. The men were very capable men & good seamen--

[left margin] Provisions [/left margin]I found a large quantity of provisions on board, beef, pork & bread. There was quite enough to 15 men for 35 days and more than enough beef. Some of the beef is yet unused. I had been serving on the Yorktown about two months previous to the seizure-- Whilst on the station I have met with individuals who seemed to have a very good knowledge of the manner in which the slave trade was carried on. I have principally derived my information from American Officers. I should think 250 slaves might have been carried from Africa to Cuba in the Patuxent-- 25 days would be rather a long voyage than a short one-- I dont know how many men would be required to take charge of a cargo of that number of slaves. 8 or 10 persons more would have been quite sufficient.

[left margin] do. Rice [/left margin] We counted 71 bags of rice on board -- sacks of old canvass. They averaged about 100 lbs apiece and over. There was a tierce of 8 barrels of rice. full. The barrels were common sized flour barrels. The allowance for each slave is generally about a pound or pint of rice apiece. A cargo of 250 slaves could have been subsisted 30 odd days on the amt of rice on board-- Rice & water is the usual food given the slaves. It was African rice a good deal

[left margin] Water [/left margin] mixed with gravel & dirt. There were 10 casks of water & 1 butt containing or capable of containing in all 1500 gallons. In that hot climate a gallon a day to a man would be a liberal allowance for drinking, cooking & washing. A pint is usually, as I have understood allowed per day

[page 3]

to each slave. There were no other water casks in the vessel to my Knowledge. I judge that 1500 galls of water is sufficient for a crew of 15 persons at a gall per day each for 30 days and at the rate of 1 pint per day for each slave for 250 slaves for 30 days. The casks could be very easily filled on the Coast of Africa in the rainy season. I shᵈ [should] judge they might have been filled in one night by spreading an awning. It is not usual for vessels of that size to make such preparations for water. It is not essential to a slaver to have a slave deck.-- We found 50 pieces of plank

[left margin] Plank [/left margin] of various lengths from 4 to 38 or 40 feet in length, most of it long: some 10 or 12 pieces of intermediate length-- This plank might have been laid as a deck in a very few minutes without either hatchet or saw without the slightest difficulty. The plank was new deck plank about six inches wide & 3 inches thick

[left margin] Stauncheons [/left margin] The Stauncheons which we found on board the vessel were not all up and such as were up were not fixtures as is usual on board of vessels carrying cargo This would afford a facility in laying a deck with planks -- Such a deck as this plank would make would be very useful in transporting a cargo of slaves,

[left margin] Arch of deck [/left margin] more so than a permanent deck. The beams of the deck were slightly arched so that the deck would be

[left margin] Deck frame [/left margin] supported even without the stauncheons. The deck frame seemed sounder than the rest of the vessel and from that I judged that it had been put in since the vessel was built-- Under the deck plank, I found a large quantity

[left margin] Pine plank [/left margin] of pitch pine plank stowed & billetted up so as to be level so that it would form a foundation for the deck plank on which it might have been laid by a few hands in a very few minutes-- I found also on board some six or seven tons of stone ballast stowed abaft the mainmast between that & the Cabin Bulkhead.

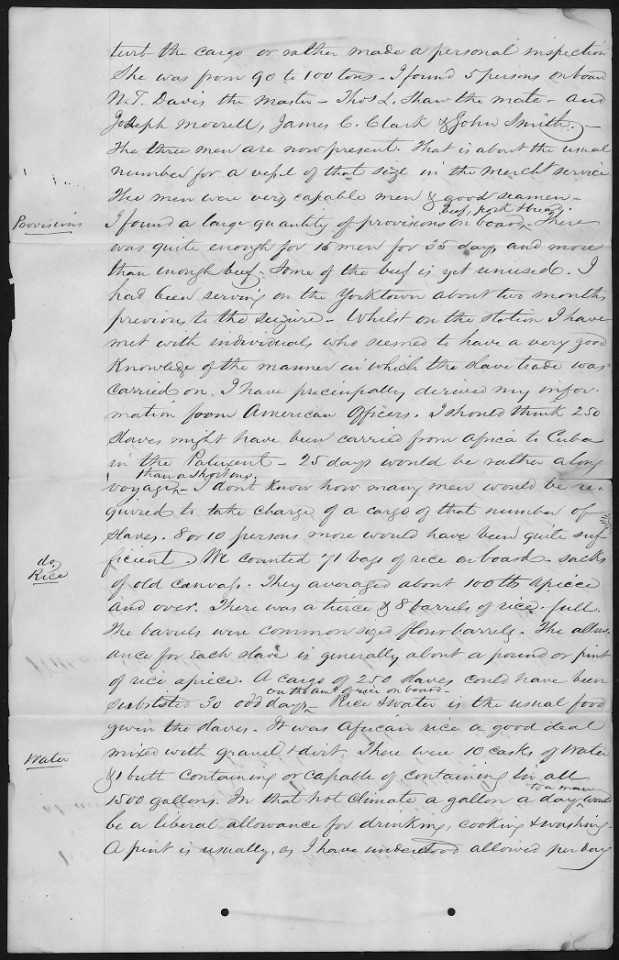

[page 4]

I found some pieces of chain in the holds. One piece about 8 fathoms & one about 5 fathoms. a small pair of chain [illegible] and a large number of assorted bolts such as come out of ships timbers rather larger than would come out of the Patuxent. a ring & bolt. some iron hooks also. a chest of old tools good for nothing. A number of spare pars ^4 spare sails ^ were found The deck could have been laid with the cargo she then had on board leaving a flush space of 4 1/2 or 5 feet under the deck. The slaves are stowed sitting, one within the legs of the other and 4 1/2 feet would have been ample. When the Patuxent was taken she was anchored about a mile from the shore.

(The Logbook of the Patuxent produced identified IS. Clark Master from June 19 1844 to 12 May 1845. Hiatus to 23 June 1845 when N. T. Davis is master. in the port of New York 26th June crew came on board. Captain, passengers & pilot went on shore Heading from N.Y. towards Coast of Africa 2 Augt. 1845. 7 a.m. made Cape Mount. 11 furled sails. Captain & passengers went on shore.

19 Augt. 1845 to 22 August Vessel lies at Cape Mount 22nd. Took in 3 passengers at Sulima for Sierra Leone. 24th at Sierra Leone. Capt. & 2 passengers went on shore.

Log Book of Brig Atalanta found on board identified 18 July 1844 commences. Johnston Martee. Heading from N.Y. to W. Coast of Africa. Arrived on coast & sailed up & down until Dec 24th 1844 Capt. told crew that vessel was sold to Capt. Canot of Cape Mount.

This last entry is in Capt. Davis's handwriting. There are other entries in the Book in his handwriting.

Is there a notorious establishment at Cape Mount for

#archivesgov#March 17#1846#1800s#antebellum#enslavement#slave ship#African American history#Black history#triangle trade#a pint is two cups--less than a 1/2 liter

56 notes

·

View notes

Text

What is L- Type Anchor Bolts?

L type anchor bolts are typically used in concrete construction.

L type anchor bolts are also known as “Tie-down” anchors because they are used to tie the structure down to the foundation. They are usually made of steel and they come in many different lengths, diameters and shapes.

L Type Anchor bolts can be used for a variety of purposes, but their most popular use is in concrete construction. L type anchor bolts are often referred to as "tie-down" anchors because they're primarily used to tie structures down to foundations. They come in many different lengths, diameters, and shapes, but all have one thing in common: they're made of steel.

0 notes

Text

L-bolts are commonly used in the development industry

L-bolts will be anchor bolts included in construction. Their length and shape make all of them Stud Bolts And Nuts Suppliers In China ideal for a number of purposes, including your attachment of sill system and post bases. They also supply general concrete anchorage in addition to meet the prescriptive requirements belonging to the National Building Code of Canada 2015. Read on to find out more about the benefits of using L-bolts throughout construction. There undoubtedly are a few things to learn about L-bolts and the way to properly use them. L-bolts are commonly used in the development industry to single point plate members to masonry foundations. They are commonly termed as 90-degree anchor bolts and now have standard applications while in the anchoring of structural tips, light poles, fill rails, and signage. These kind of anchor bolts supply maximum strength plus durability, due on the bent part in the shaft, which stops it from coming loose. They are available in various sizes and materials and have varying thread diameters. An L-bolt is required in construction projects to carry structural elements constantly in place. L-bolts are typically cast into concrete and offer resistance for embedded tangible foundations. They can even be used in hold-down bolt parrot cage configurations to safe and sound steel panels. They can be found in M12 to M36 diameter and can be found in plain steel in addition to 304 or 316 s / s. They are the best option for several applications. They are also a good solution for securing a heavy stone system. The most typical use for L-bolts is designed for attaching plate customers to masonry foundations. These bolts are also called 90-degree anchor bolts. Some of the common uses of L-bolts consist of anchoring structural posts, light poles, bridge rails, and signage. The bent portion on the L-bolt adds sturdiness and prevents it from coming free. There are lots of sizes and materials for L-bolts, with thread diameters including M6 to M16. L-bolts may be used for anchoring structural aspects in concrete as well as masonry. They reject earthquakes, wind, and other forces that causes the structure to transfer. Because they are made from strong, high-quality components, L-bolts provide a substantial foundation. However, they're just expensive and could be difficult to find. They are critical for building in addition to constructing structures. Regardless of their function, L-bolts are essential for structural sincerity. L-bolts are employed for building construction. They can be familiar with secure heavy boulders in concrete. The L-bolts may be formed into a new loop when found in construction. It can also be used for different uses, like holding up heavy diamond blocks. It is vital to note that L-bolts is the most commonly utilised anchor bolts in foundations. A foundation may be a strong structure as well as a foundation is essential for the stable structure. L-bolts are commonly used in engineering and engineering. They are widely used to charge objects to real. Their threaded end is threaded. They can be purchased in different materials, like zinc, hot-dip galvanized, and black oxide. You can choose the ideal one to your requirements. The materials and sizes of L-bolts can vary a whole lot. They are as well used for the various models of bolts, which include things like anchors, nut, as well as washers.

0 notes

Text

Foundation Bolt Manufacturer

Foundation bolts are essential components used in construction and heavy machinery for anchoring structures to the foundation. Typically made from high-strength steel, these bolts provide stability and support to structures like buildings, bridges, and towers. Foundation bolts are designed to withstand extreme loads and stresses, ensuring the structural integrity of the foundation. They come in various shapes and sizes, including L-shaped, T-shaped, and straight bolts, depending on the specific application. The bolts are embedded in concrete during the foundation phase and secured tightly to hold equipment or structures in place. With their critical role in safety and durability, foundation bolts are a key part of modern engineering, offering reliability in diverse industries, from construction to manufacturing.

0 notes

Text

What is Another Name for a Foundation Bolt? | Common Terms & Alternatives

If you're involved in construction or civil engineering, you’ve likely come across the term foundation bolt. But did you know that foundation bolts are often referred to by different names depending on the region, industry, or specific application? Whether you're a contractor, DIY enthusiast, or engineer, understanding the various terms associated with foundation j bolts can help you make more informed decisions when sourcing or specifying these critical components.

In this article, I’ll walk you through common names for foundation bolts, what they’re used for, and how to choose the right one for your project.

Common Names for Foundation Bolts

Foundation bolts are integral components used in construction to anchor structures like buildings, bridges, or machinery to their foundations. While foundation bolt is the most widely recognized term, several alternative names are commonly used in the industry. Here are a few terms you might encounter:

Anchor Bolts

One of the most common alternatives for foundation j bolts is anchor bolts. This term is often used interchangeably with foundation bolts because their primary purpose is to anchor a structure to its base, such as a foundation or slab.

Why it's used: Anchor bolts are critical for securing large structures to prevent movement or shifting. They come in various shapes and sizes to suit different load-bearing requirements.

Where it's used: Construction sites, machinery installations, and heavy structural work.

J-Bolts

J-bolts are another term for foundation j bolts, particularly when they are shaped like the letter "J". These bolts are bent into a J-shape at one end, allowing them to hook into the concrete or foundation for a more secure hold.

Why it's used: J-bolts are commonly used when a curved or hooked bolt is needed for more effective anchoring.

Where it's used: Concrete foundations, bridge construction, and structural foundations.

L-Bolts

L-bolts are also referred to as foundation bolts when they are designed with a 90-degree bend in the shape of the letter "L". This shape ensures a secure attachment, similar to J-bolts, but with a different style for various applications.

Why it's used: L-bolts are useful for applications where a sturdy and consistent alignment is needed, often used in steel and wooden foundations.

Where it's used: Heavy construction, steel structure anchoring, and wood foundation installations.

U-Bolts

Although U-bolts are more commonly associated with pipe and tubing installations, they can also serve as foundation bolts in specific construction settings. The "U" shape allows the bolt to encircle and hold components securely in place, especially when additional support is needed.

Why it's used: U-bolts are ideal for securing pipes, tubes, or structural supports to concrete foundations.

Where it's used: Commercial buildings, infrastructure projects, and pipeline installations.

Stud Bolts

While stud bolts are technically different from traditional foundation bolts, they are sometimes used interchangeably, especially when the fastening component involves threaded rods. These bolts can be cut to various lengths and used for a variety of anchoring purposes.

Why it's use3d: Stud bolts are often threaded at both ends and are used in applications that require flexibility in the positioning of the bolt or fastening.

Where it's used: Mechanical engineering, equipment mounting, and structural fastening.

Why Foundation Bolts are Essential in Construction

Now that you know the different names for foundation bolts, you may be wondering why these components are so essential. Let’s break it down:

Securing Structures: Foundation bolts are critical for anchoring buildings, bridges, and other heavy structures to the ground. Without the proper anchor or foundation bolt, a structure can shift or settle unevenly, which could lead to costly damages or even safety hazards.

Providing Stability: Foundation bolts offer long-term stability by ensuring that structural elements stay securely in place. Whether it’s a J-type foundation bolt or an anchor bolt, these fasteners keep your building steady and resistant to environmental forces like wind, earthquakes, or soil movement.

Ensuring Safety: A properly installed foundation bolt contributes to the overall safety of the structure. Whether you’re using a U-bolt, L-bolt, or stud bolt, these fasteners prevent accidents that might occur from an unstable foundation.

Types of Foundation Bolts

To ensure you are using the correct foundation bolt, it’s important to know the different types available and their specific uses. Here’s a quick overview:

Anchor Bolts: Generally used for securing structural components to foundations, available in various shapes such as J-bolts, L-bolts, or U-bolts.

J-Type Foundation Bolts: These are designed with a hook at one end to anchor the bolt securely into the concrete. Ideal for foundation work where the bolt needs to hook into the slab for stability.

L-Bolts: Similar to J-bolts, but the bend is at a 90-degree angle, making them great for installations where the bolt needs to hold something at a right angle.

U-Bolts: Typically used to secure pipes or tubes to foundations, these bolts are useful when you need to form a tight loop around objects.

Stud Bolts: These threaded bolts can be used when adjustable lengths are required, making them versatile for a range of applications.

Conclusion

Whether you call it a foundation bolt, anchor bolt, J-bolt, or any of the other names mentioned, the key takeaway is this: foundation bolts are essential for ensuring the integrity and stability of a structure.

When you’re choosing a foundation bolt, make sure to:

Consider the type of structure you are securing (e.g., a building, bridge, or machine).

Select the right shape based on whether you need a hook (like J-bolts) or a straight connection (like L-bolts or U-bolts).

Understand the material options (such as stainless steel shims or shim washers) that will work best for your environmental conditions, such as exposure to moisture or extreme temperatures.

Knowing the different terms used for foundation bolts can help you communicate more effectively in the construction industry. Whether you are working with shim washers, precut shims, foundation bolts, or anchor bolt manufacturers, understanding their terminology and applications ensures you make the right decisions for your projects.

#foundationbolts#anchorbolts#fasteners#construction#hardware#engineering#building#constructionindustry

0 notes

Text

Foundation Bolts Manufacturer, Supplier & Exporter India | BigBoltNut

We are engaged in manufacturing, supplying & exporting of heavy foundation bolts from India. We have vast range of foundation bolts for pre-engineered buildings manufacturing, fastening heavy machines to foundations and construction. Foundation bolts are mainly used in pre-engineered buildings manufacturing, fastening heavy machines to foundations, and construction. They are also used in process-based businesses like petrochemical, sugar, and FMCG manufacturing. These Foundation Bolts are available in different variety of types including “L” type foundation bolts, J Type foundation bolt, anchor nut foundation bolt, Plate type foundation bolts.

0 notes

Text

Introduction to Bolts: Types and Applications

Bolts are fundamental components in construction, manufacturing, and various other industries. They play a crucial role in holding together different parts of a structure or machinery, ensuring stability, strength, and safety. Bhansali Fasteners is one of the leading Bolt Manufacturers in India. Several prominent bolt manufacturers in India are well-known for producing high-quality products with a broad market reach. LPS Bossard, a joint venture with Switzerland's Bossard, produces precision fasteners.

Types of Bolts

Hex Bolts

Description: Hex bolts are characterized by their hexagonal heads and are one of the most common types of bolts used in various applications.

Applications: These bolts are widely used in construction, machinery, and automotive industries due to their strength and versatility. They are suitable for fastening wood, steel, and other construction materials.

Carriage Bolts

Description: Carriage bolts have a rounded, dome-shaped head with a square section underneath the head. This square section prevents the bolt from turning when a nut is tightened.

Applications: Commonly used in wood applications, such as securing wooden panels or beams, carriage bolts are also found in metalwork and construction projects where a smooth, finished appearance is desired.

Lag Bolts

Description: Lag bolts, also known as lag screws, are large, heavy-duty fasteners with coarse threads. They have a hexagonal head and are designed for use with a wrench or socket.

Applications: These bolts are ideal for heavy-duty applications, such as securing heavy wood beams, wooden structures, and large machinery. They provide strong, reliable fastening in both wood and masonry.

Anchor Bolts

Description: Anchor bolts are used to attach structures to concrete. They come in various shapes, including L-shaped, J-shaped, and straight rods with threads on one end.

Applications: Widely used in construction for securing foundations, columns, and heavy equipment to concrete bases, anchor bolts are essential for ensuring stability and safety in buildings and structures.

U-Bolts

Description: U-bolts are shaped like the letter "U" with threads on both ends. They are used to secure pipes, tubes, and other round objects to a surface.

Applications: Commonly used in plumbing, automotive, and construction industries, U-bolts are essential for fastening pipes, exhaust systems, and other cylindrical objects.

Eye Bolts

Description: Eye bolts feature a loop (or eye) at one end and threads on the other. They are designed for attaching ropes, cables, or chains.

Applications: These bolts are used in rigging, lifting, and suspension applications. They are commonly found in construction, marine, and industrial settings where secure attachment points are needed.

Materials and Coatings

Bolts are manufactured from various materials, each offering different levels of strength, corrosion resistance, and durability. The most common materials include:

Steel: The most widely used material for bolts due to its strength and affordability. Steel bolts are often coated with zinc or galvanized to enhance corrosion resistance.

Stainless Steel: Known for its excellent corrosion resistance and strength, stainless steel bolts are ideal for outdoor and marine applications.

Brass: Provides good corrosion resistance and electrical conductivity, making brass bolts suitable for electrical and decorative applications.

Titanium: Lightweight and extremely strong, titanium bolts are used in aerospace, medical, and high-performance applications where weight and strength are critical.

Applications of Bolts

Construction Industry

Bolts are used extensively in construction for assembling structural steel frameworks, securing foundations, and attaching heavy components. Hex bolts, anchor bolts, and lag bolts are particularly common in this industry.

Automotive Industry

In the automotive sector, bolts are used to assemble engines, chassis, and other vehicle components. Carriage bolts, hex bolts, and U-bolts are often used to secure parts and ensure the integrity of vehicles.

Manufacturing and Machinery

Bolts are crucial in manufacturing for assembling machinery, equipment, and industrial components. Eye bolts, hex bolts, and lag bolts provide the necessary strength and reliability for heavy machinery and industrial applications.

Marine Industry

In marine applications, stainless steel bolts are preferred for their corrosion resistance. These bolts are used to secure components on ships, docks, and offshore structures.

DIY and Home Improvement

Bolts are commonly used in DIY projects and home improvement tasks, such as building furniture, installing shelves, and constructing outdoor structures. Carriage bolts and hex bolts are popular choices for these applications.

Bhansali Fasteners is one of the major Bolt Suppliers in India. Bolts Suppliers in India.low-maintenance, sustainability benefits, and adaptability for fluid transportation in industries such as oil and gas, chemical, food, pharmaceuticals, and construction. They provide reliability and safety. Bolt Suppliers in India is known for its industrial fasteners, which include high-quality bolts, nuts, screws, and washers.

0 notes

Text

Forged Automobile Parts manufacturers suppliers

RATTAN INDUSTRIES (INDIA) has achieved specialization in manufacturing and export of Railway Fasteners, Railway Bolts Nuts Fasteners, Road Crash Barrier Fasteners, High Tensile Hex Bolts, High Tensile Hex Nuts, Anchor Foundation Bolts / U Bolts, Eye Bolts / Forged Eye Bolts, T Bolts / J Bolts / L Bolts, Hot Forging Items, Railway Electrical Fasteners, Threaded Rods / Thread Bars, Threaded Studs, Hot Forging Fasteners etc. we are also manufacturer exporters suppliers of all other Hot Forging Companies in India, Hot Forging Components, Hot Forging Products, Hot Forging items, Forged Automobile Parts Forging, Forged Railway Fasteners, Forged Railway Bolts Nuts, Forged Railway Components, Forged T Bolts, Forged Eye Bolts, Forged Road Crash Barrier Fasteners, Forged High Tensile Bolts, Forged High Tensile Nuts, Forged Anchor Foundation Bolts, Forged Automobile Components, Forged Automobile Parts, Forged Yokes, Forged harvester Fingers, Forged Agriculture Parts, Forged Tractor Parts, Forged Wheel Nuts, Forged Wheel Bolts, Forged Gear Shafts & Flanges, Forged Turn Buckles, Forged Poleline Hardware, Forged Scaffolding Couplers, Forged Formwork Accessories, Forged Castle Nuts, Threaded Rods Bars, Threaded Studs, Forged Tractor Parts, Automotive parts Forgings, Agriculture Parts Forgings, Fasteners Forgings, Steel Components Forgings, Forged Nuts Bolts, Forged Flanges, Forged Agriculture Implements, Customized Forgings, Forged Bolts Nuts in india, ludhiana punjab usa, uk, America, UAE Dubai, australia, italy, canada contact number +9195925-42700, +91-92161-34270 [email protected] https://www.rattaninds.com

1 note

·

View note

Text

Foundation Bolts vs. Anchor Bolts: Understanding the Differences and Applications

Introduction

When it comes to construction projects, two types of bolts play a vital role in ensuring the stability and structural integrity of various structures: foundation bolts and anchor bolts. While they may appear similar, understanding their differences and knowing when to use each type is crucial for a successful and secure construction project. In this article, we will explore the disparities between foundation bolts and anchor bolts, shedding light on their unique characteristics and applications.

Foundation Bolts

Foundation bolts, as the name suggests, are specifically designed to provide a strong connection between a structure and its foundation. These bolts are typically embedded into the concrete foundation during the initial construction phase, ensuring a secure and stable base. Foundation bolts are often used in applications such as:

Building Construction: Foundation bolts are extensively used in the construction of buildings, where they securely connect the building's structural components to the foundation. This helps in distributing the weight of the structure and resisting external forces like wind and seismic loads.

Machinery Installation: Foundation bolts are crucial for installing heavy machinery, such as generators, turbines, or large equipment. These bolts anchor the machinery to the foundation, preventing movement or vibrations that could affect the machine's performance or cause damage.

Bridge Construction: Bridges require a solid connection between their substructure and the foundation. Foundation bolts are used to secure bridge piers, abutments, and other components to ensure stability and load-bearing capacity.

Anchor Bolts

Anchor bolts, on the other hand, are designed to provide a secure attachment point to concrete or masonry structures. Unlike foundation bolts, anchor bolts are typically installed after the concrete has cured or the masonry has been laid. They serve various purposes, including:

Structural Attachments: Anchor bolts are commonly used to attach structural elements to concrete or masonry, such as steel columns, beams, walls, or partitions. These bolts ensure a strong and stable connection, allowing the structure to resist vertical and lateral loads.

Equipment and Machinery: Anchor bolts are crucial for securing equipment and machinery to concrete floors or foundations. They are often used in industrial settings, such as manufacturing plants, where heavy machinery needs to be firmly anchored to prevent movement during operation.

Fixtures and Installations: Anchor bolts are employed to secure fixtures like handrails, guardrails, signposts, and parking bollards. These bolts provide a solid foundation, ensuring safety and stability in public spaces, commercial buildings, and outdoor structures.

Distinguishing Factors

While both foundation bolts and anchor bolts serve the purpose of providing stability and security, there are notable differences between them:

Installation Timing: Foundation bolts are installed during the initial construction phase, embedded directly into the concrete foundation. In contrast, anchor bolts are installed after the foundation or concrete has cured.

Embedment Depth: Foundation bolts are typically embedded deeper into the foundation to achieve a secure connection, while anchor bolts may have varying embedment depths depending on the specific application.

Design and Shape: Foundation bolts often have a straight, L-shaped, or J-shaped design, depending on the requirements. Anchor bolts can have a wide range of shapes, such as L-shaped, J-shaped, U-shaped, or wedge anchors, to accommodate different structural needs.

Conclusion

Understanding the differences and applications of foundation bolts and anchor bolts is essential for any construction project. Foundation bolts provide a solid connection between a structure and its foundation, while anchor bolts serve as secure attachment points for various structural elements, equipment, and fixtures. By selecting the appropriate type of bolt and employing them correctly, construction professionals can ensure the stability, safety, and longevity of their projects.

As a leading construction supplier, Prontofabril offers a wide range of high-quality foundation bolts and anchor bolts to meet the diverse needs of construction professionals. Our experienced team is ready to assist you in selecting the right bolts for your project, ensuring optimal performance and reliability

0 notes